Feldschlösschen has strongly centralised its logistics in recent years. Since the production and distribution warehouse at the main location in Rheinfelden does not offer sufficient capacity in its current form, Feldschlösschen has developed a logistics master plan. As part of this plan, various locations on the plant site were evaluated for the construction of a high-bay warehouse. On this basis, offers and concepts for automated storage and order picking were obtained from various system suppliers.

Information customer

Feldschlösschen, headquartered in Rheinfelden AG, is the leading brewery and largest drinks retailer in Switzerland. The company has existed since 1876 and employs 1200 people at 21 locations throughout Switzerland. With a range of over 40 of its own Swiss brand beers and a comprehensive beverage portfolio ranging from mineral water to soft drinks and wine, Feldschlösschen supplies 25,000 customers from the catering, retail and beverage trade.

Project goals & tasks

Evaluation of the available offers and concepts for automated storage and picking

Elaboration of a holistic solution proposal

Preparation of the findings for the preparation of a final business case

Results at a glance

- Evaluation of existing offers and comparison of strengths, weaknesses and costs of the individual offers and solution approaches

Development of a final, holistic solution proposal

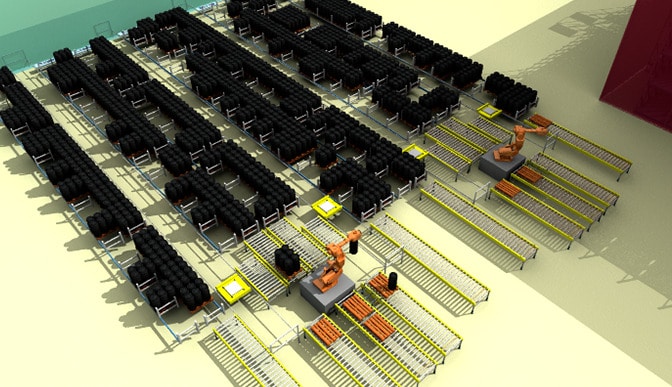

Analysis of existing restrictions due to building and usage regulations with design plan obligation - Development of solution variants for the integration of a high-bay warehouse with approx. 40,000 pallet spaces and a multi-level and largely automated picking area into the existing building

- Cost verification in cooperation with industrial architects and international suppliers

- Preparation of all findings for the development of a business case for the strategic evaluation of the investment project

- Concept validation within the international project team with members from both Feldschlösschen and Carlsberg A/S