The company Otto Christ AG operates a logistics centre at the Benningen site. This is to be expanded as the company grows. The aim of the expansion of the logistics is to unbundle the current flow of goods and to be able to organize the logistical processes including the production supply more efficiently.

Information customer

Otto Christ Wash Systems has been one of the leading manufacturers of car wash systems in Europe since 1963 with a company size of approx. 1,400 employees. Their product range is deeply tiered and extends from the portal car wash known in everyday life to special systems for various types of vehicles.

Project assignment

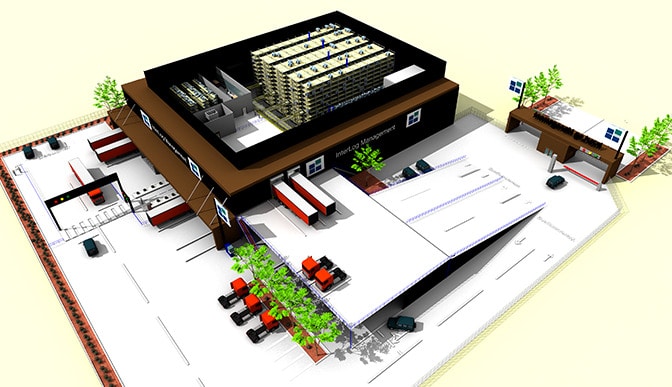

The project assignment included the complete plant structure planning of the logistics center at a new location as well as the optimization of the intralogistic processes. Further components were the connection of the goods and transport flows between the existing plant and the new logistics location as well as the preparation of an implementation plan.

Results at a glance

- Consideration of the actual situation including the intralogistic processes as well as the customer characteristics

- Development of different concept variants for the optimization of intralogistic processes

- Storage infrastructure and storage methodologies

- Automation possibilities

- Transport and handling areas

- Plant structure planning and the planning of the new logistics center

- Investment cost calculation / ROI calculation from process potentials

- Determination of investment costs for the intralogistic infrastructur

- Investment cost calculation for the construction of the logistics buildings

- Creation of the implementation planning